Research

-

Overview

We are researching and developing two kinds of innovative motors that contribute to energy conservation and greenhouse gas reduction. For one thing, we are analyzing, designing, prototyping, experimenting and evaluating switched reluctance motors that realize high performance without using rare earth magnets, aiming at application to main motors of electric vehicles and hybrid cars. Another is, as a next-generation motor, we are conducting fundamental research on a magnetically levitated bearingless motor that magnetically supports a rotating shaft by electromagnetic force without using mechanical bearings.

The research theme of this laboratory is the contents of electricity, machinery, information and electronics, and you can acquire a wide range of knowledge and skills. In addition, we value the design, prototyping, and experiment of the actual machine.Through research on motors, you can learn the importance of manufacturing.

◆Research Content

Bearingless drive, Switched reluctance drive

◆Field of study, Keyword

Power electronics, Magnetic levitation engineering, Electric Machinery, Control engineering, Electric power engineering,Magnetic bearing, high speed rotation, electric motor, generator, high efficiency drive, inverter, digital control

-

ANSYS Academic Program Partner

ANSYS Academic Program Partner

Bearingless Drive

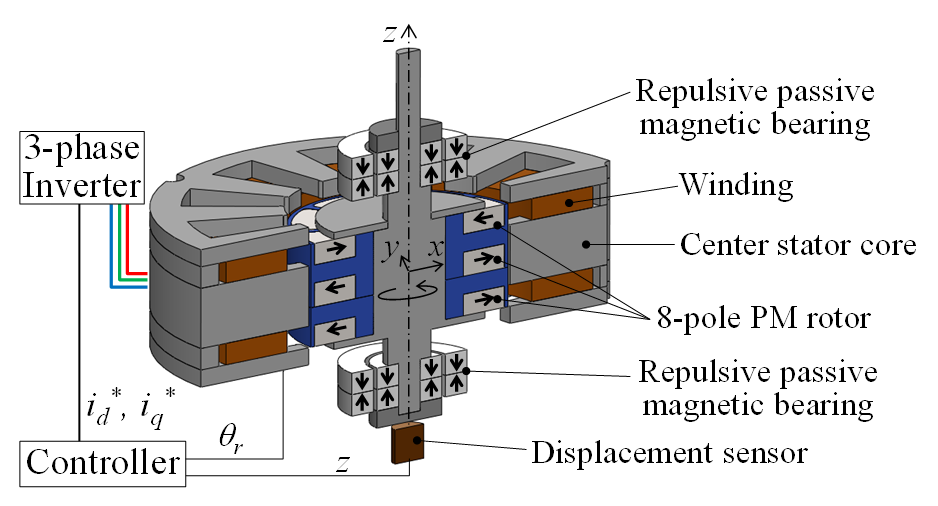

"Floating and rotating" Magnetic levitation bearingless motor

A motor that does not require a mechanical bearing and magnetically supports the rotating shaft by electromagnetic force.

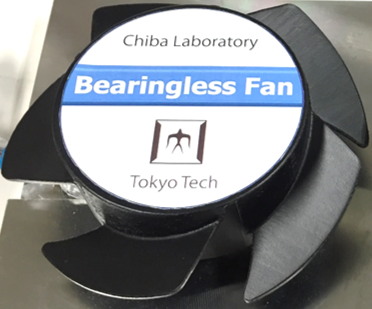

In recent years, miniaturization, high speed and high efficiency of motors have progressed, and the demand is expected to increase in the future.However, with the current mechanical bearings, the rotational speed is limited because machine loss increases at high speed rotation in genera. Therefore, in our laboratory, we are engaged in research and development of bearingless motors that do not require mechanical bearing and can magnetize the rotating shaft noncontactly by electromagnetic force.

Since the bearingless motor has advantages such as no friction, no wear, maintenance free, etc., it is not limited to high-speed rotation applications, but it can be used not only for applications with many failures of bearings, for applications requiring continuous operation for a long time or for locations where maintenance is difficult.Therefore, we are researching and developing for application to cooling fan, wind power generator, etc.

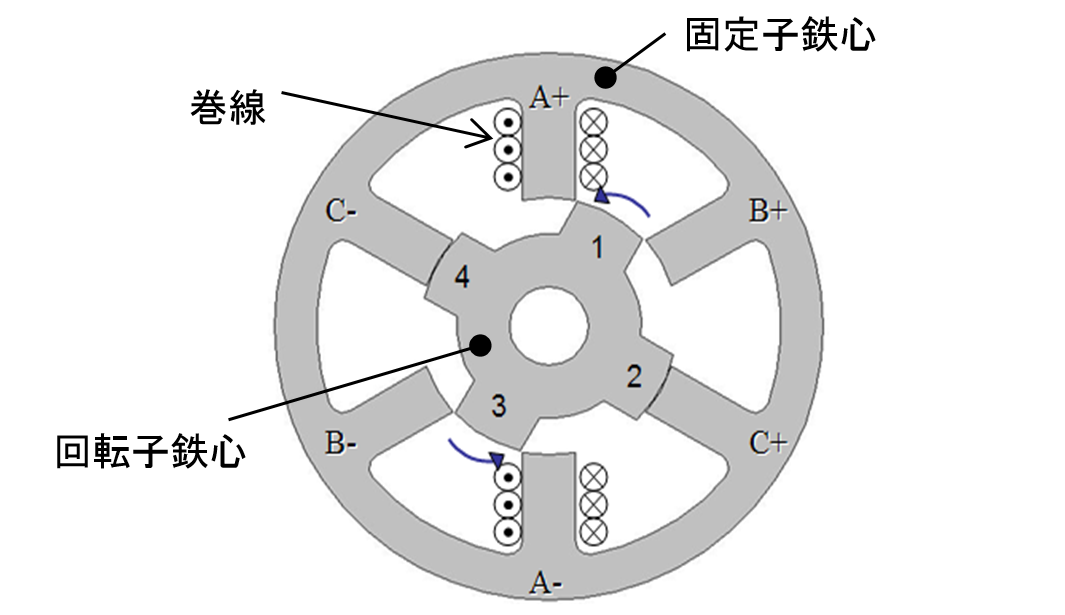

Switched Reluctance Drive

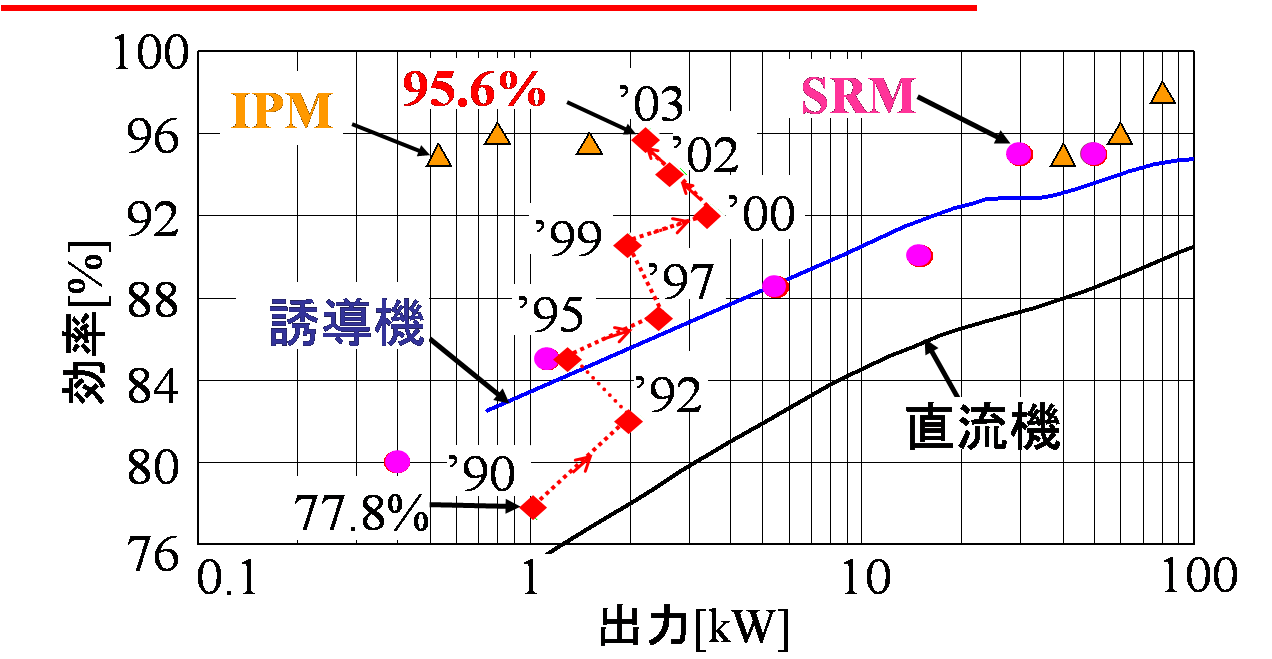

The Switched Reluctance Motor (SRM) has the advantage that it is inexpensive and robust because the stator and the rotor are composed only of the iron core and the winding and do not use the permanent magnet. Currently, permanent magnets are used for the main motor of commercial hybrid vehicles, but due to concerns about rare earth supply uncertainty and price fluctuations, interest in SRM without using permanent magnets is increasing.

However, the switched reluctance drive has the following four problems.

(i) Low torque density

(ii) Ineffective

(iii)Use a special inverter

(iv) Vibration and noise are large

We boldly challenge these difficult tasks and have carried out R & D on the motor structure to solve (i) (ii). At the design stage, we create a 3D model of the motor, simulate it using magnetic field analysis software, and examine the structure. Even if good simulation results come out, the results are not evaluated only by the results, and the experiment results are important. We have produced a 60 kW actual size prototype that can generate the same torque and output with the same physique as that for hybrid vehicles and demonstrated its effectiveness experimentally.

The result of this research is the world's first case experimentally proved with actual size prototype that SRM can provide performance comparable to permanent magnet motor. And this research achievement has attracted attention from companies and universities.

Reduction of vibration and noise

The vibration and noise of SRM is an issue from 20 years ago and there are many papers on reduction methods, but there was no remarkable reduction effect.

In this laboratory, we were working on this research theme around 2012, but we did not get results in the first two years. We proposed an innovative method that reduces vibrations and noises by applying current so as to reduce pulsation of the sum of the radial forces of the stator yoke part around 2014. And demonstrated its effectiveness experimentally .

In this research theme, we clarified the mechanism by which the vibration and noise of SRM can be drastically reduced by constructing basic theory by mathematical expression, verification by numerical simulation using magnetic field analysis, and experimental verification using prototype machine. This research achievement has made a great contribution not only in academic value but also in industrial applications.